CC Aqua Blasting Ltd

The Vapour Blasting Specialists

Quality Finishing with Attention to Detail

Vapour Blasting Parts Cleaning Service

Surface Finishing to Perfection using our Unique Dual Vapour Process.

Vapour Blasting Components for Restoration and Industry.

Superior to any dry media process and standard vapour blasting.

We dual surface finish for the following:

- Restoration Companies - Classic and Vintage Vehicles.

- Individual Car and Motorcycle Enthusiasts.

- Engine Builders.

- Machining companies - Machined Aluminium and Stainless Components.

- Aerospace.

- Motorsport.

- Kit Car Builders - Donor part preparation.

- Welding Companies - post weld finishing.

- Electroplaters and Anodisers - consistent surface prep.

- Scooter Specialists - Lambretta / Vespa.

Our process:

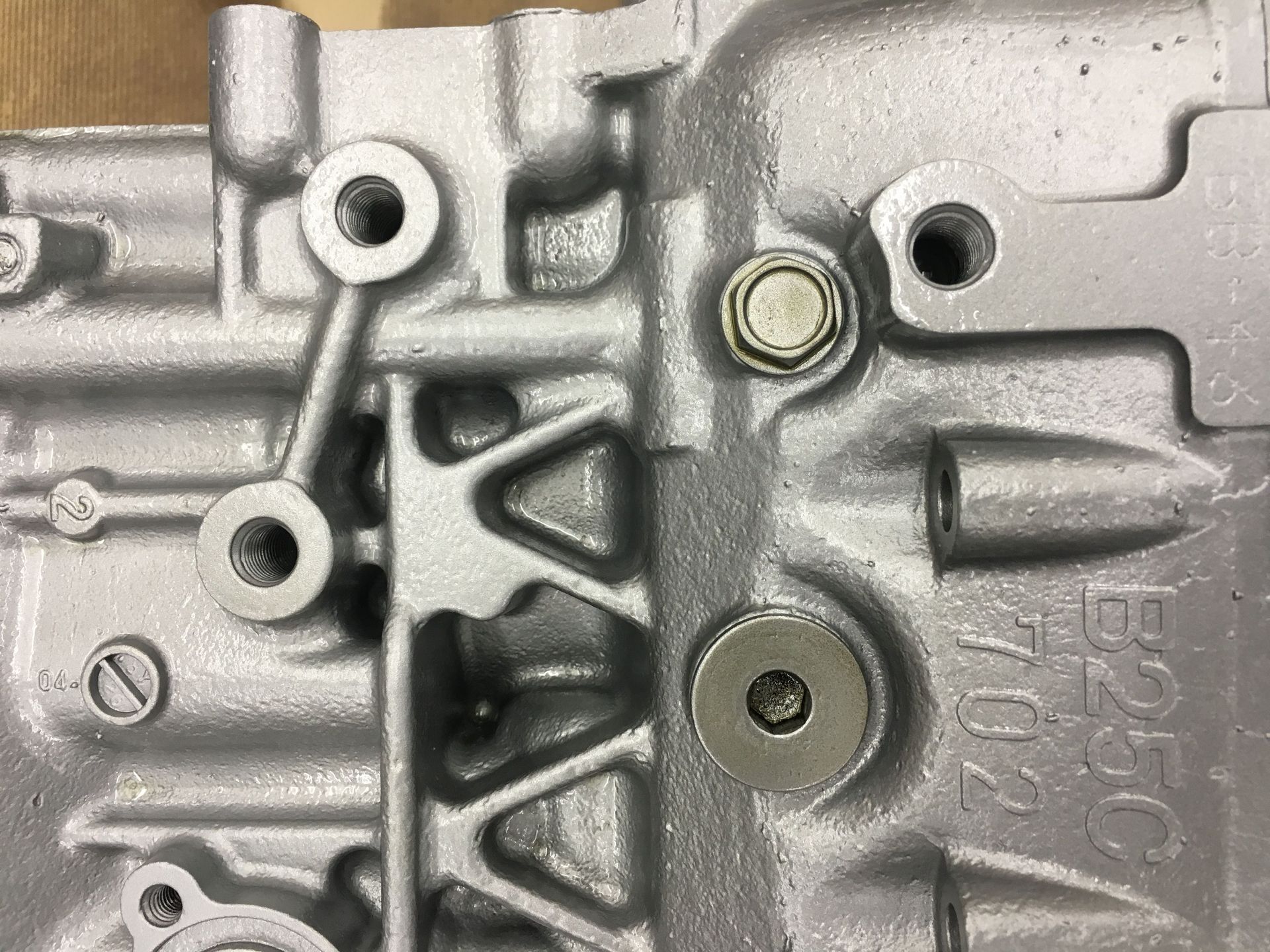

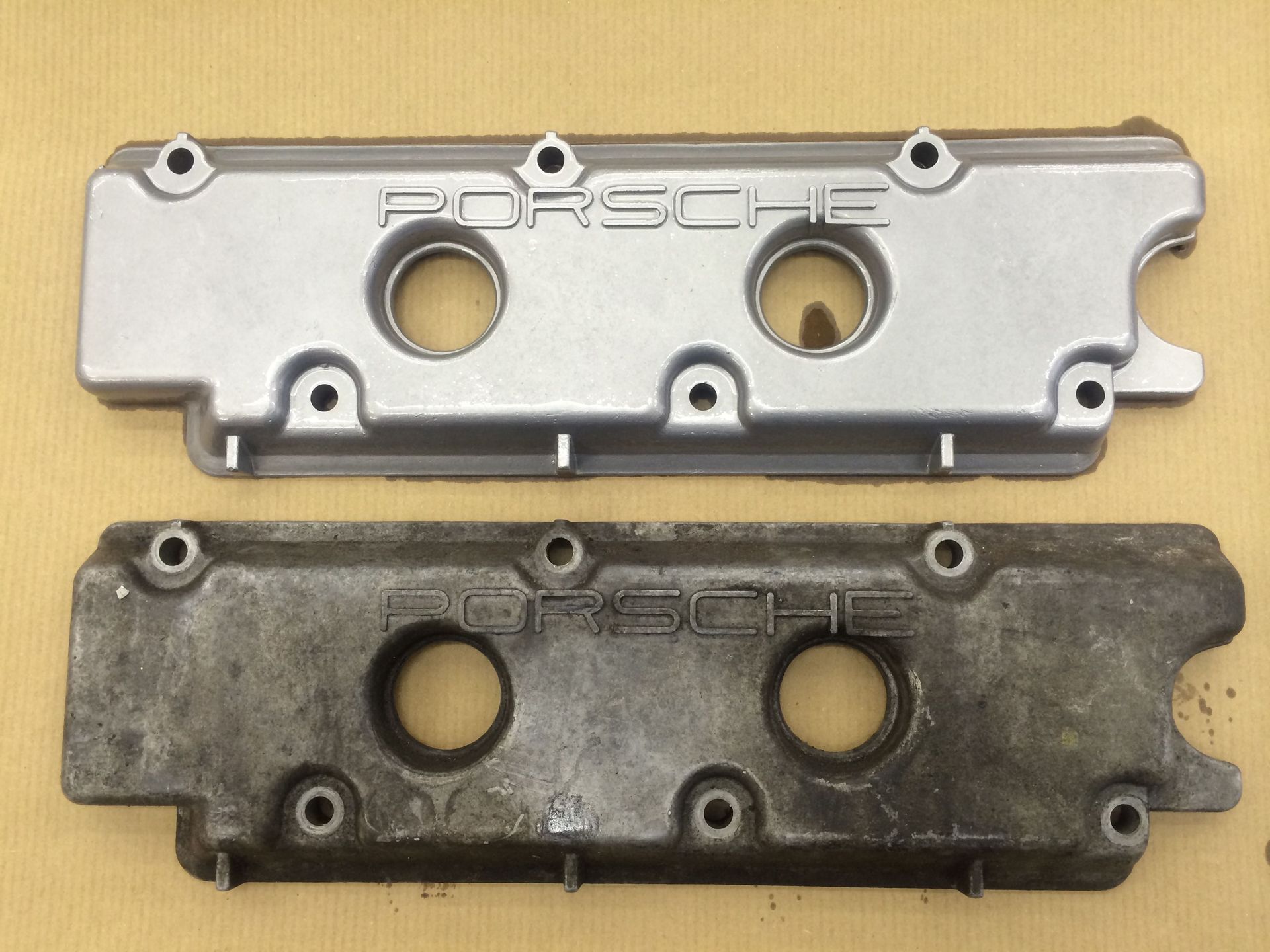

- Removes soiling and oxidation

- Unlike dry blasting gently peens without abrading the surface.

- Provides a consistent finish

- Removes discolouration

- Micro peens to help resist re-soiling and oxidising.

- Sympathetically cleans using our non-aggressive method.

- Does not remove component detail.

CC Aqua Blasting Ltd is based in Little Bentley , Essex

We operate using 5 Modified Vapour Blasting machines with our own carbide splitter nozzles using our developed dual vapour method and the highest quality spherical media blended to our own specifications.

We surface finish components up to 1 metre in length.

We welcome any quantity of parts from a single component through to batch processing.

We don't operate with a minimum charge. No job too small !

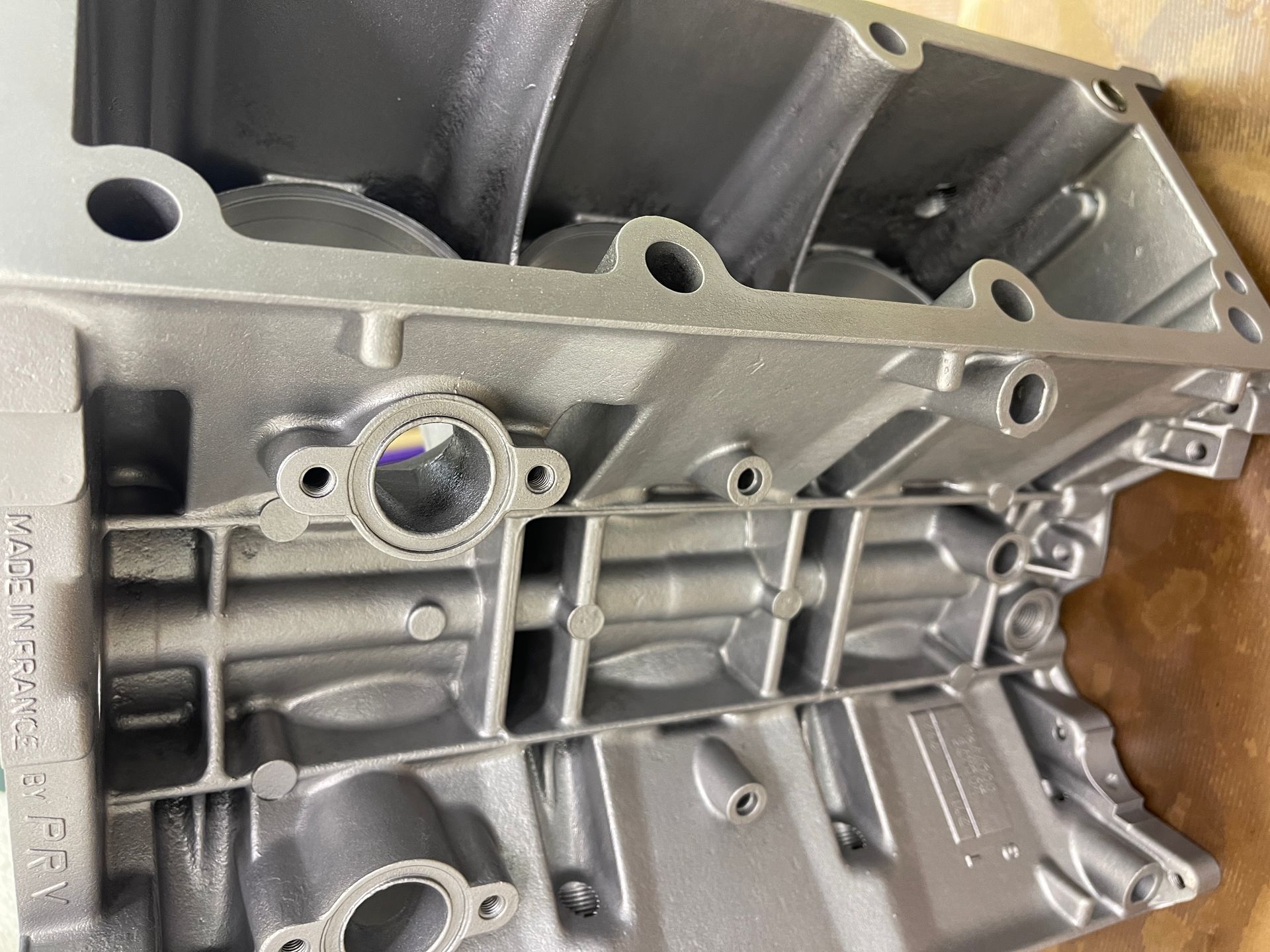

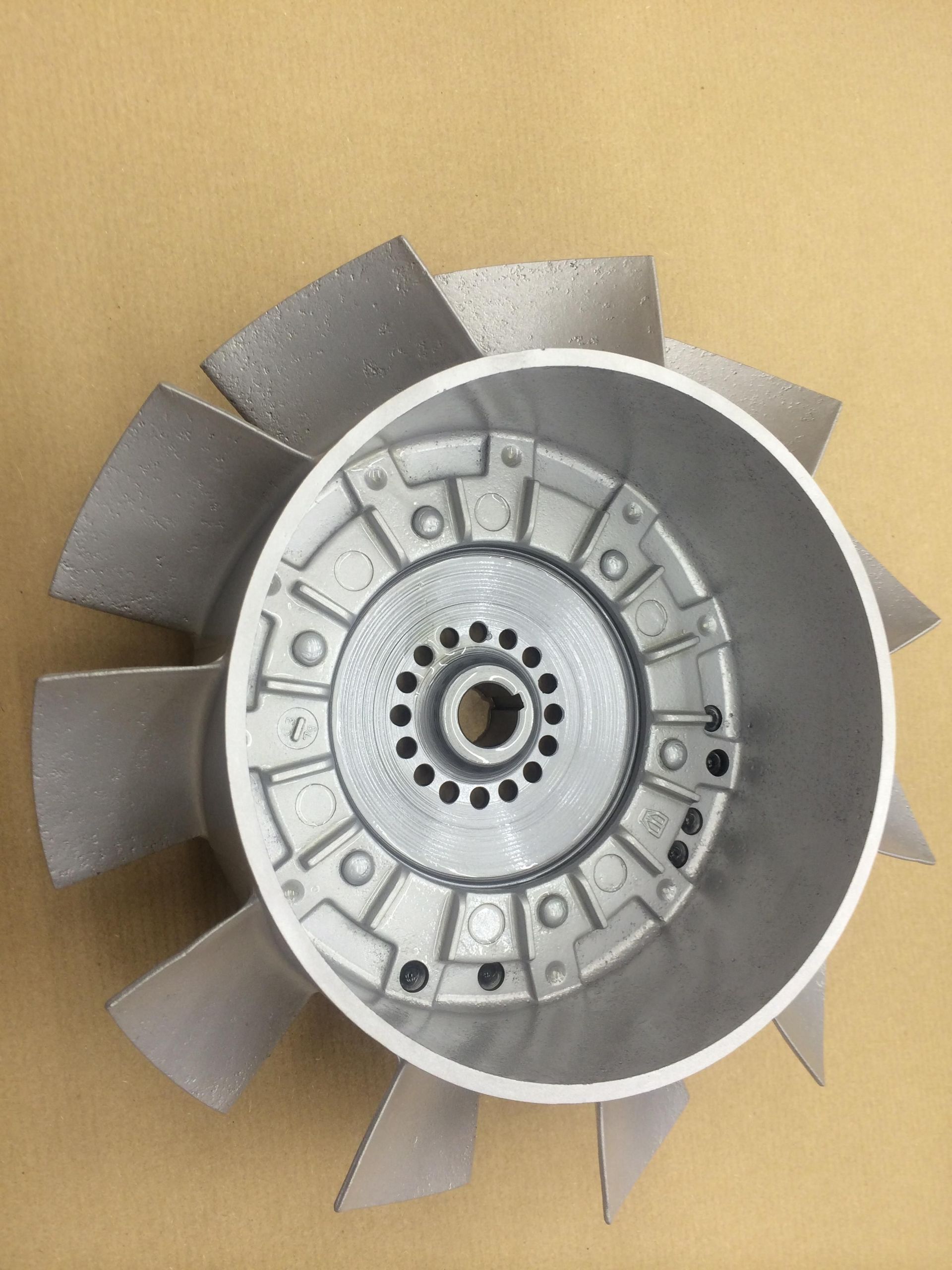

Our Unique Dual Vapour Blasting Process

We offer a unique process which gives a significantly improved finish over regular vapour/aqua/wet blasting.

We have developed our process over the last 9 years and our current dual process offers the best possible finish for your Classic Car and Motorcycle components.

We cosmetically finish parts from Aluminium , Magnesium , Copper , Brass , Bronze , Titanium and Stainless Steel.

We also finish parts from Steel prior to any electroplating service.

We use our own selected and consistently blended media to finish your parts to the highest standard possible.

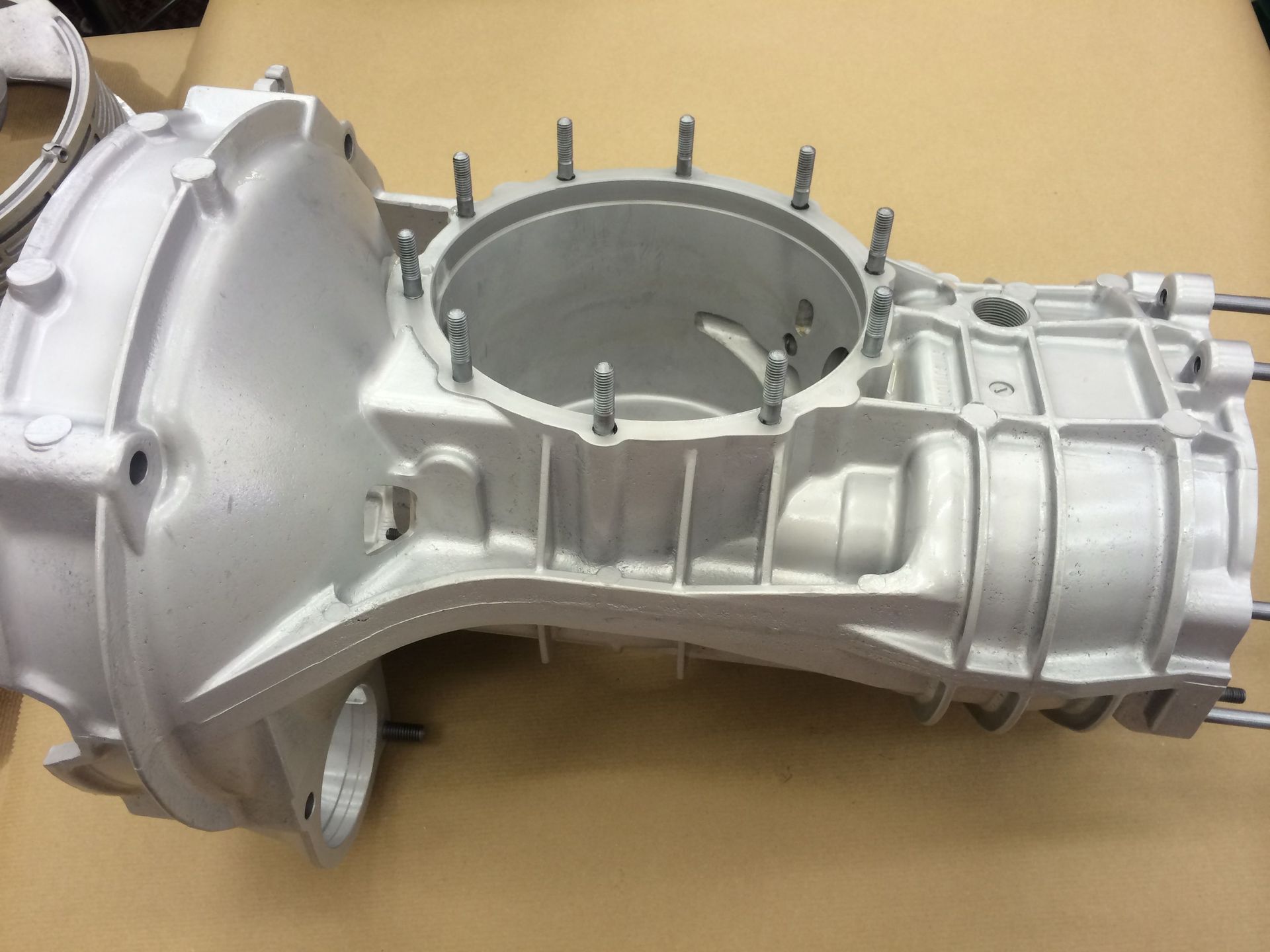

We finish Engine and Gearbox Casings , Cylinder Heads , Cylinder Blocks , Carburettors , Engine Covers , Water Pump Housings ,

Motorcycle and Car Wheel Hubs , Suspension Arms etc..... - in fact most components made from the above materials.

Our process is non aggressive and unlike any dry media blasting leaves a smooth satin "easier to clean" surface.

Parts must be supplied completely stripped down with all bearings and seals removed - Plain bushings , studs and dowels can remain fitted.

All parts must be reasonably degreased.

Price Guide

All work is quoted on inspection of components - Either in hand or with emailed photographs.

My prices are competitively based on the surface area and complexity of each component.

Prices are based on using our Dual Vapour Method which provides the very best available surface finish.

Parts can be delivered to us in person by appointment or sent in to the address on the about us page.

Please carefully pack all parts in substantial packaging when sending using carriers.